What Happens to Solar Panels and Turbines at the End of Life?

3. Monitor the panels for any electronics or technical issues, like frayed wiring, indicators which indicate that an electrical connection failed, etc.

Solar panels have been a key part of our pursuit of cleaner energy, but like any tech, they've got a limited lifespan. Usually, a solar panel lasts about 25 to 30 years.

During this time, their effectiveness drops off gradually, resulting in reduced electricity production. This power dip isn't sudden, but rather develops over time, similar to how batteries run down.

Although still usable after 25 years, panels will generally slow down noticeably, so replacing them helps to maintain their top performance.

I'm ready to assist with paraphrasing in an Australian English dialect. Please provide the original text for paraphrasing.

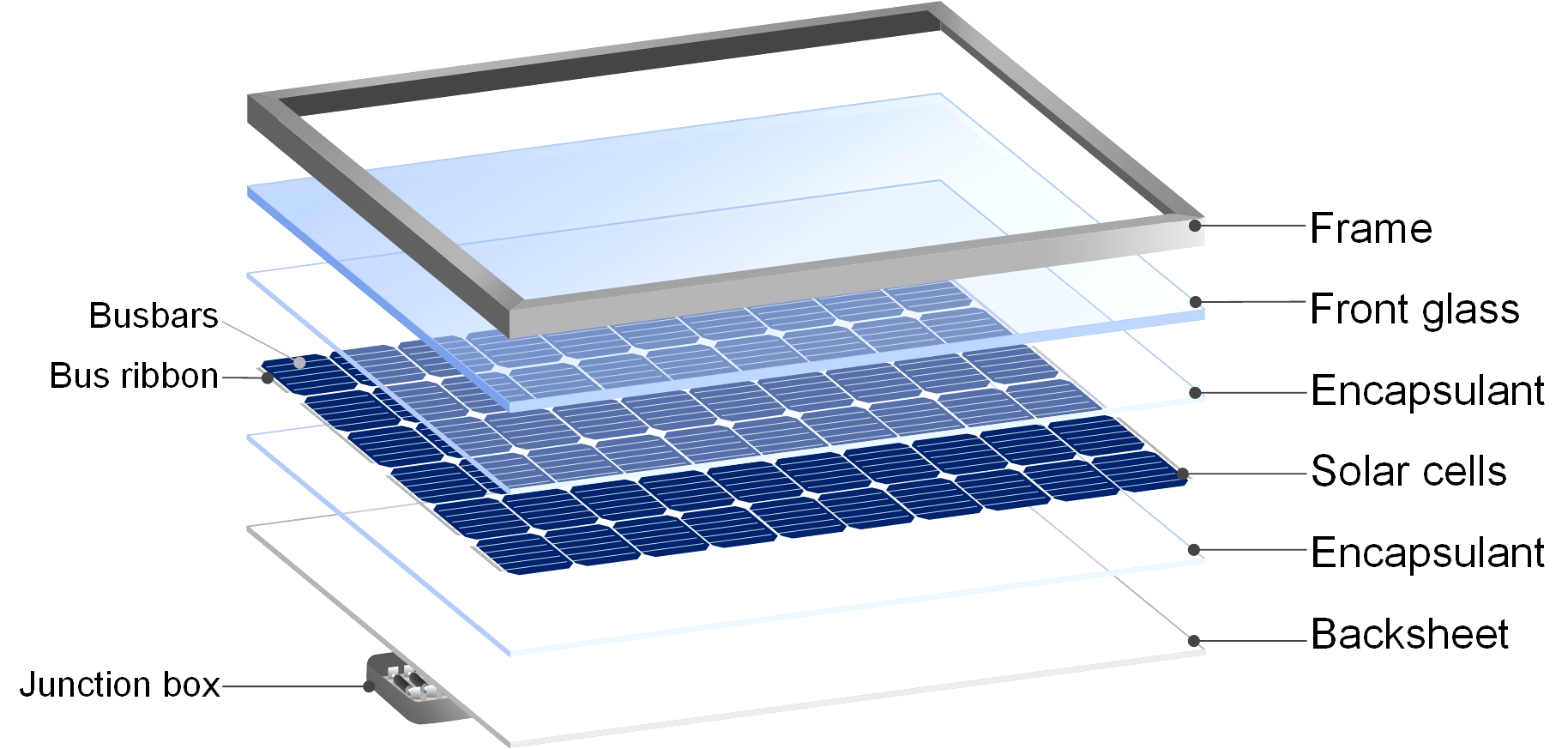

Getting a handle on the materials that go into solar panels is critical when it comes to chipping in or getting rid of 'em when they're no good. Most panels are mainly made of silicon, with an aluminium frame, toughened glass, and a few other components.

These components have some worth to 'em, and can be given a second life or brought back. The trouble is, their fancy design makes it hard to break 'em down and recycle 'em.

The same silicon that grabs sunlight can be recovered, but the process is complicated and expensive.

* Conserves resources to manufacture other essential goods

The good news is that solar panel recycling is an emerging commercial activity. In Europe, explicit regulations require recycling practices.

New businesses are popping up with innovative ways to recover and reuse components. Yet, in many countries, the industry is still in its early stages of development.

If we don't have recycling, those panels just end up in landfills, which creates environmental issues. It's a bit like tossing out a smartphone with valuable parts just because the screen's smashed.

There's a pressing need to develop more effective methods and policies to cope with this situation.

"...it's like building a very tall, spinning top with rotating blades - just multiply that by hundreds, since there are hundreds of turbines at work in a typical wind farm," says Jarrett Adams.

Wind turbines, towering symbols of renewable energy, face challenges at the end of their life cycle. They have an operational lifespan of approximately 20 to 25 years.

Unlike solar panels, their decline isn't about efficiency but degeneration through physical wear and tear. The massive blades and mechanical components cop it from constant movement and harsh climatic conditions.

Once their operational days are done, decisions need to be made about those massive buildings.

Metallic components represent a considerable portion of a wind turbine's mass. These include massive steel components such as the foundation, tower, and generator bed. The intentions of the operators of wind farms are to maintain pristine condition of these components to avoid wearing down wind turbines. Other metals, such as copper and aluminium, dominate the rest of the major components like blades, gearbox, and control systems. Developing environmentally friendly processes and standards for recycling these components could lead to increased reuse of valuable materials, energy conservation, and decreased construction time.

Recycling wind turbines isn't as straightforward as it sounds. The massive blades, often made from composite materials like glass-reinforced polymer, are a real challenge.

In Australia, the old-fashioned ways of recycling often can't properly break down these materials either effectively or affordably. It's a bit like trying to slam a square into a round hole.

Lots of blades end up in tip. On the other hand, towers and other metal parts have a clear path to recycling, thanks to the well-established metal recycling industries.

3. **Disassembly and material recovery:** Separating recyclable materials, such as glass fibre, steel and polymers, from collected non-recyclable components

While challenges exist in recycling, progress is being made thanks to innovation. R&D efforts are centred on designing more recyclable blades and exploring fresh uses for materials.

In Australia, it seems some companies are converting old blades into components for things like other industries, art or building designs. This is a real-life illustration of the old saying, "One man's rubbish is another bloke's treasure," in the renewable energy world.

Policy and Regulation in End-of-Life Management

Policy plays a crucial role in managing the lifespan of solar panels and wind turbines. Some countries have already acknowledged the significance of regulations that guarantee equipment recycling.

However, more consistently applied international policies can promote more beneficial practices. It's similar to how cars' emission standards were introduced due to regulatory pressure.

With a firm policy backing, the renewable energy sector can plan more effective end-of-life solutions.

* Evaluate the product and provide feedback to manufacturers who try to meet their needs

One's got a role to play, being blokes who make the goods, as well as the bloke on the couch. Picks made by the bloke with the wallet to get products from chaps who genuinely care about looking after the earth during the item's last days.

On the flip side, manufacturers gotta come up with ways to responsibly recycle materials. Luring consumers to return old panels or blades for recycling, just like returning bottles for a refund, is a pretty slow-growing trend.

It's an eco-friendly cycle that we've got to get on board with to make renewable energy completely environmentally friendly.

What are your thoughts on this subject? Let us know by posting a comment below. We're keen to hear from you! Want to stay up to date with more stories? Follow us so you don't miss out!

Posting Komentar